Weight 5KG-6KG

Logo: Ensuring the Ingot is Manufactured by us

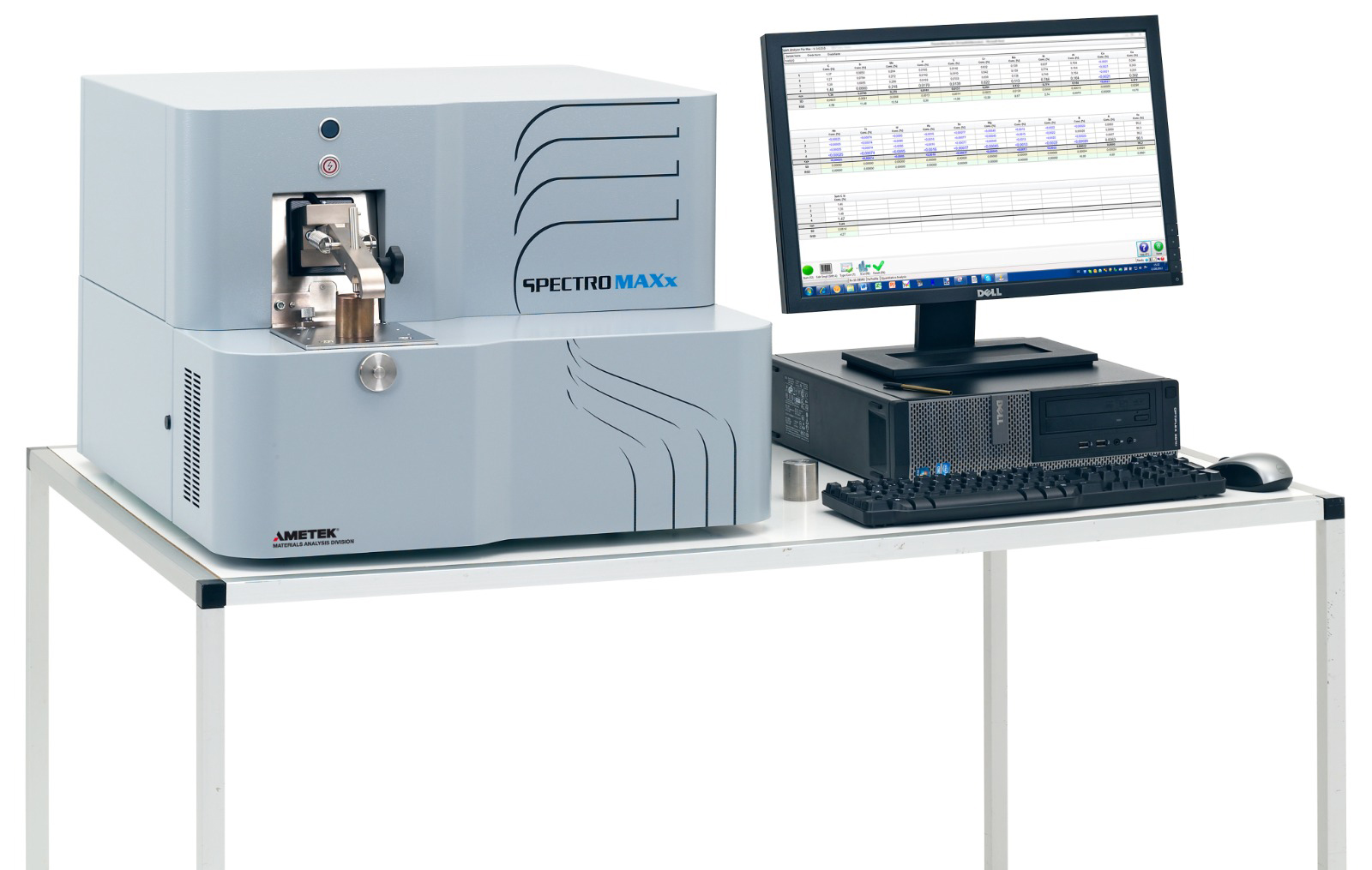

Spec Check: Spectrometer

Ingot Thickness

Aluminium Sow

An Aluminum Sow is a sizeable rectangular ingot formed by casting molten aluminum. Acting as a vital step in aluminum production, sows are used as building blocks for various products. These ingots come in different sizes, weighing from hundreds of kilograms to several metric tons, designed for easy handling and transport.

Aluminum sows are a crucial source for creating items like sheets, plates, and profiles through processes like rolling and extrusion. They’re also recycled to recover valuable aluminum content, supporting sustainability. By serving as a bridge between smelting and product creation, aluminum sows are key to industries like automotive, aerospace, construction, and packaging, underlining their pivotal role in our modern world.

Aluminium Ingots

Aluminum ingots, a prominent non-ferrous product, result from the meticulous process of pouring molten aluminum into specialized molds. These molds, available in diverse sizes and configurations, yield ingots with distinct visual characteristics. Presently, aluminum ranks as the world’s second most utilized metal, second only to iron.

The extensive integration of aluminum across industries has ignited a focused pursuit of its identification and extraction from domestic mining reserves. This surge in demand underscores the paramount role that aluminum plays in modern industries, compelling careful exploration and extraction to meet the evolving needs of various sectors.

Screening of Waste

Smelting Process

Check Sample Using Spectrometer

With the Spectrometer, Eastern Metal is able to produce wide range of aluminium alloys to follow JIS(Japan), LM(British), AA(U.S.A), and any international specifications and most imortanty it has the ability to produce aluminium ingot to your specific engineering requirements.

Casting

Product Storage

AUTOMATED STACKING

ROBOT HAND IS BEING USED TO PICK AND STACK THE ALUMINIUM INGOTS AS A BUNDLE. WITH THE USE OF THE ROBOT HAND, MANPOWER USAGE IS REDUCED AND STACKING OF THE ALUMINIUM INGOT HAS BEEN EASIER AND LESS TIME CONSUMING.